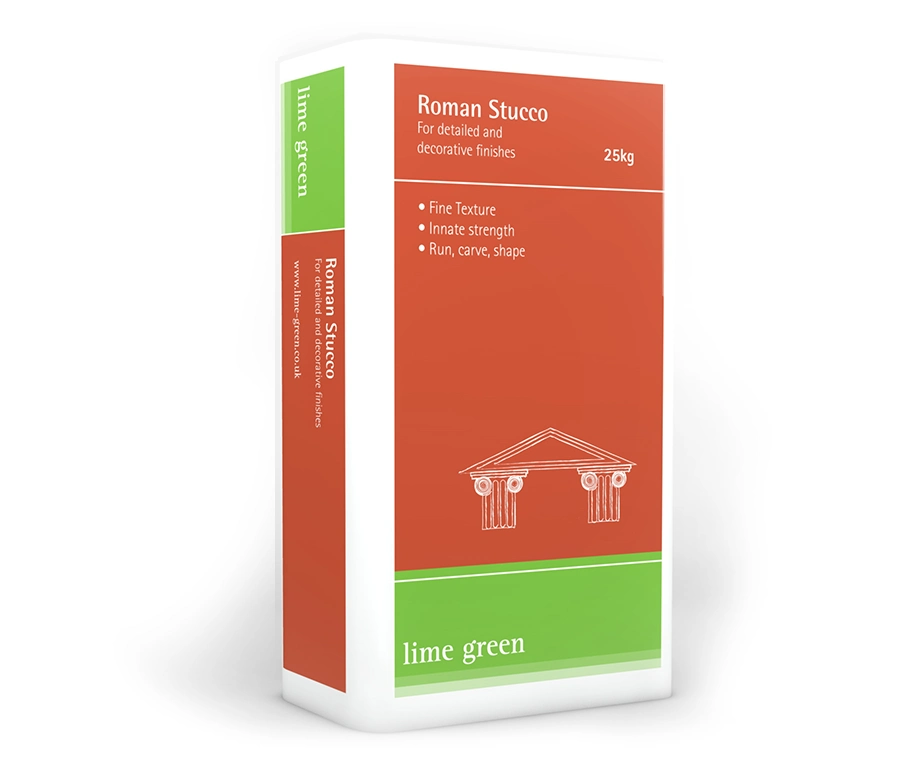

Roman Stucco Render

Stucco has been historically used as an exterior wall render to create highly detailed and decorative render finishes on building facades, such as those on the many fine Regency and Victorian houses of London, Cheltenham, Hastings, Leamington Spa and many other towns. Lime green Roman Stucco is based upon a Roman cement, a traditional binder invented around 200 years ago, which gives a unique and beautiful finish. Like lime renders, Roman Stucco is flexible and breathable and has excellent resistance to weather.

Product uses

- Matching Roman cement

- Running mouldings

- Decorative render

- Imitate stonework

Product Gallery

Photographs showing examples of projects and works that have used Roman Stucco Render.

Data Sheet

View technical information about this product here. If you require any other information please contact us

Downloads

Click on a button to download an associated document. The document will save to your downloads folder

Product advice and expert help

We're always here to help. From advice on the right products to choose, to U-value calculations and much, much more. Click here to contact our technical support team.

Related case studies

Don't just take our word for it, see what some of the leading professionals in the UK are saying about our products.

Related products

More fantastic products that might be helpful