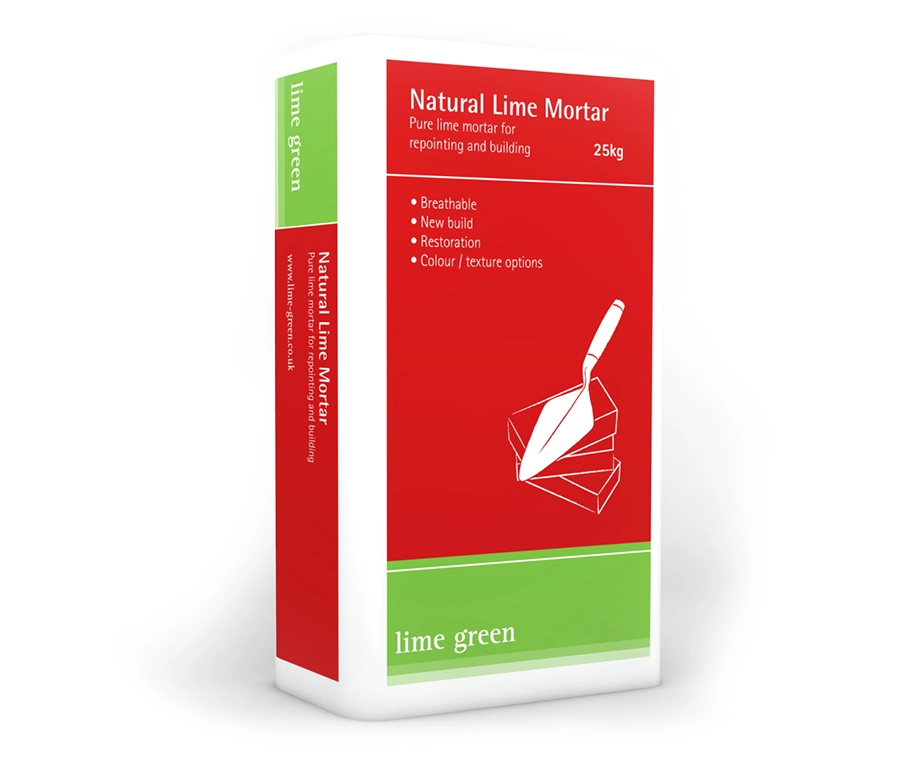

Natural Lime Mortar

Our Natural Lime Mortar is made form soft porous feebly hydraulic to highly durable eminently hydraulic, our lime mortars can be used for internal or external works and come in many different colours and two textures, perfect for achieving the best possible match with any existing brickwork or a particular building style, including lime mortar for old buildings that need a compatible, breathable mix.

It also works well as a lime mortar for stone walls where a compatible, breathable mix is needed, including lime mortar repointing and lime pointing repair on older or weathered masonry.

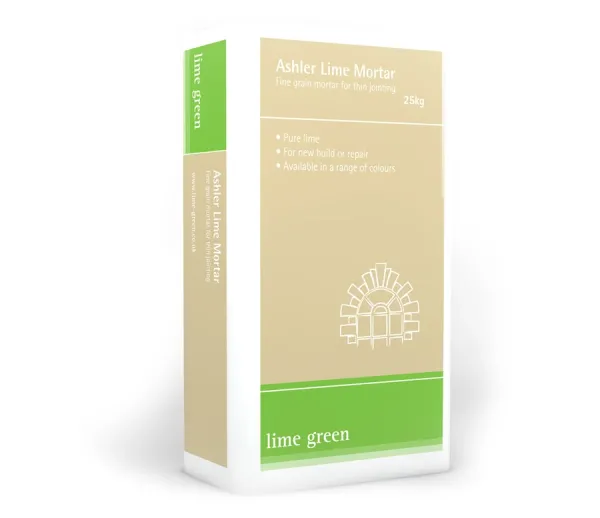

Lime Green lime mortars are available pre-packed in 25kg paper sacks for smaller jobs or can be delivered in 1000kg bulk bags as required. If you are working on a larger project then we can tailor the mix to your specific requirements.

Product uses

- Repointing brick and stone

- Brick slips

- Building new walls

- Not suitable for paving

- Internal and external use

Product Gallery

Photographs showing examples of projects and works that have used Natural Lime Mortar.

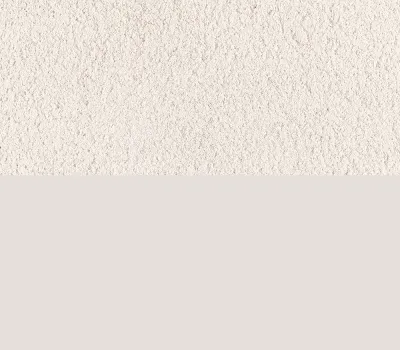

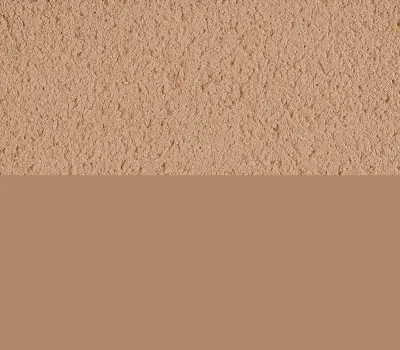

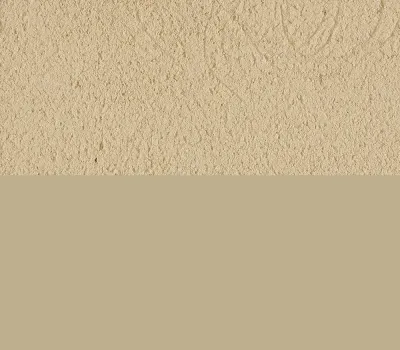

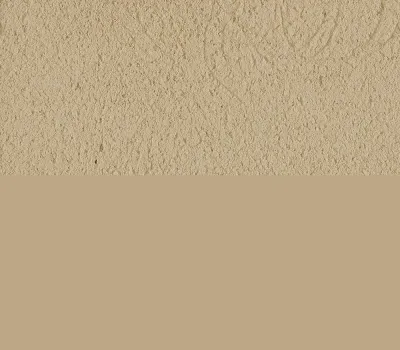

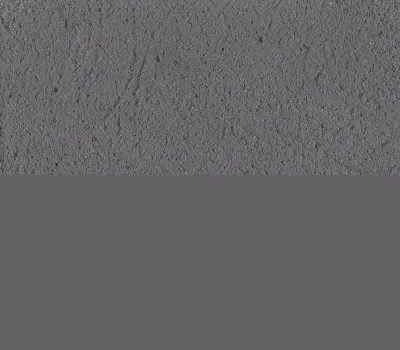

Colours

Use this colour chart to narrow your choice of finishes then get in contact with us for your your colour samples.

Please note that colours on screen may vary from actual finishes.

Order colour samples here

Our colour samples are the perfect way to find your ideal shade. Whether you want to compare favourites or see the colour in situ, you can easily order them from us.

Chalk

More products >

Tugford

More products >

York

More products >

Grinshill

More products >

Bath

More products >

Purbeck

More products >

Honeysuckle

More products >

Birch

More products >

Tallow

More products >

Terracotta

More products >

Barley

More products >

Cotswold

More products >

Stone

More products >

Earth

More products >

Salmon

More products >

Farringdon

More products >

Ochre

More products >

Ironstone

More products >

Corfton

More products >

Bracken

More products >

Harnage

More products >

Cinders

More products >

Penrhyn

More products >

Autumn

More products >

Data Sheet

View technical information about this product here. If you require any other information please contact us

Downloads

Click on a button to download an associated document. The document will save to your downloads folder

Product advice and expert help

We're always here to help. From advice on the right products to choose, to U-value calculations and much, much more. Click here to contact our technical support team.

Related case studies

Don't just take our word for it, see what some of the leading professionals in the UK are saying about our products.

Related products

More fantastic products that might be helpful

Pure Lime Grout

Ashlar Lime Mortar