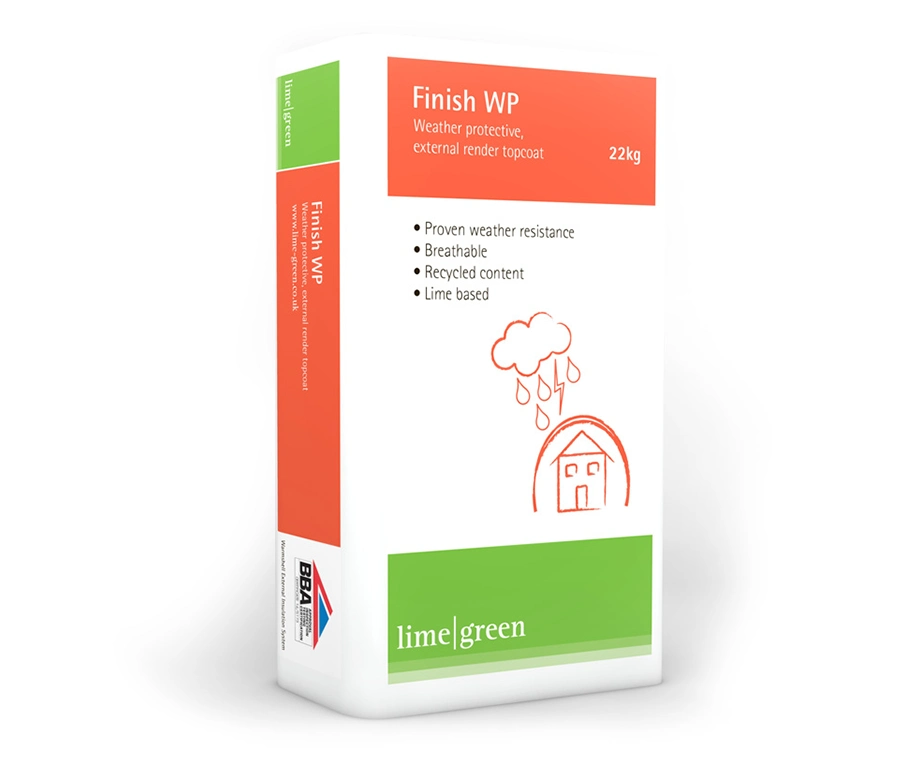

Finish WP External Lime Render

It has exceptional water resistance while remaining highly breathable. Available in a range of colours and textures.

Special additives in this external lime render offer the very best protection against rain and other elements. This creates a long-lasting and stable finish with built-in colour that greatly reduces the need for maintenance and repair.

So, use Finish WP lime render and not only will you save on the cost and time of painting, but then won't have to worry about paintwork flaking or being knocked and revealing another colour beneath.

Product Gallery

Photographs showing examples of projects and works that have used Finish WP External Lime Render.

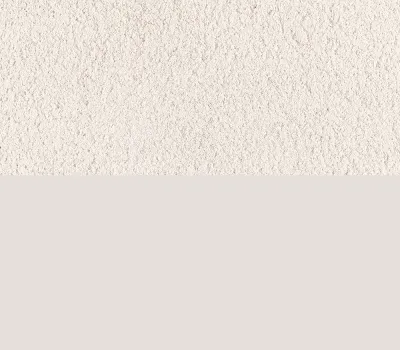

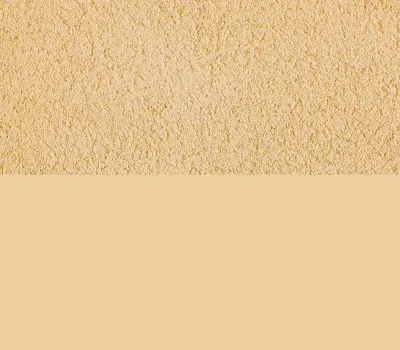

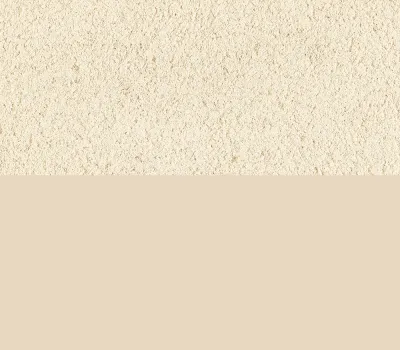

Colours

Use this colour chart to narrow your choice of finishes then get in contact with us for your your colour samples.

Please note that colours on screen may vary from actual finishes.

Order colour samples here

Our colour samples are the perfect way to find your ideal shade. Whether you want to compare favourites or see the colour in situ, you can easily order them from us.

Chalk

More products >

York

More products >

Grinshill

More products >

Bath

More products >

Purbeck

More products >

Honeysuckle

More products >

Birch

More products >

Tallow

More products >

Barley

More products >

Cotswold

More products >

Stone

More products >

Earth

More products >

Salmon

More products >

Ochre

More products >

Ironstone

More products >

Corfton

More products >

Bracken

More products >

Harnage

More products >

Data Sheet

View technical information about this product here. If you require any other information please contact us

Downloads

Click on a button to download an associated document. The document will save to your downloads folder

Product advice and expert help

We're always here to help. From advice on the right products to choose, to U-value calculations and much, much more. Click here to contact our technical support team.